A07 – Polymeric foams and oxide-coated materials

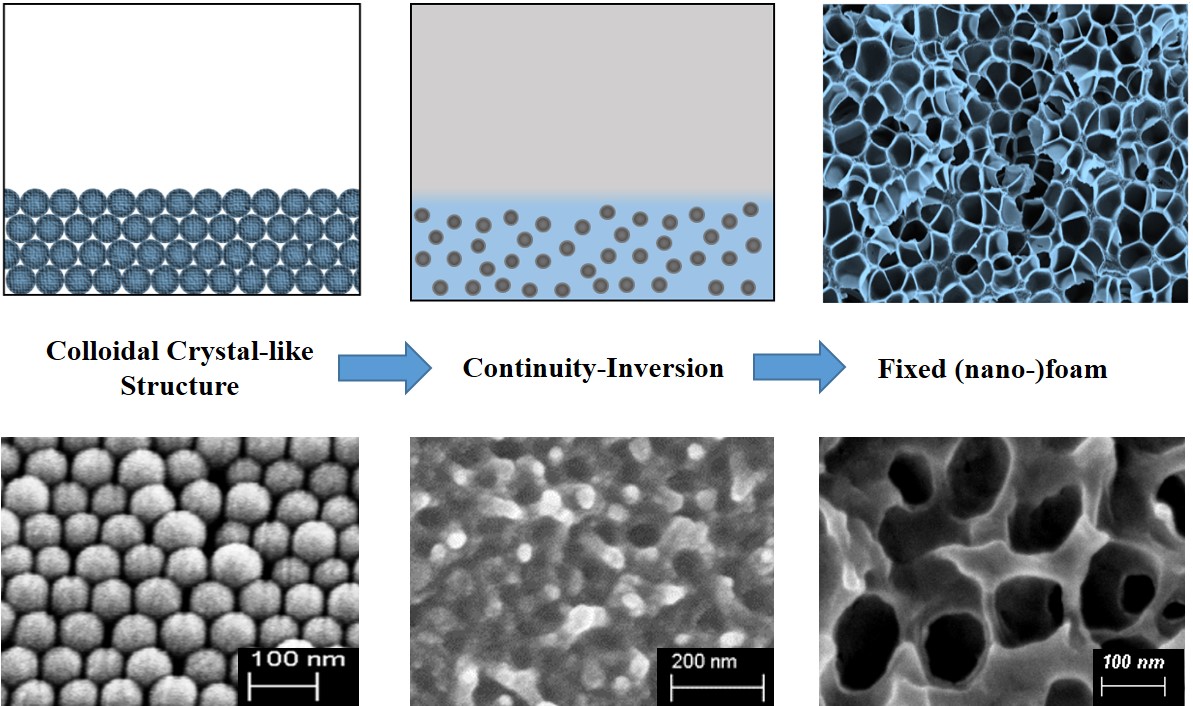

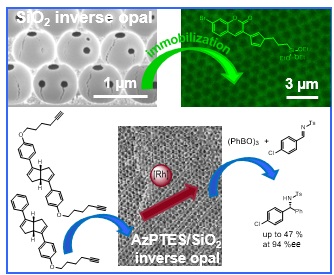

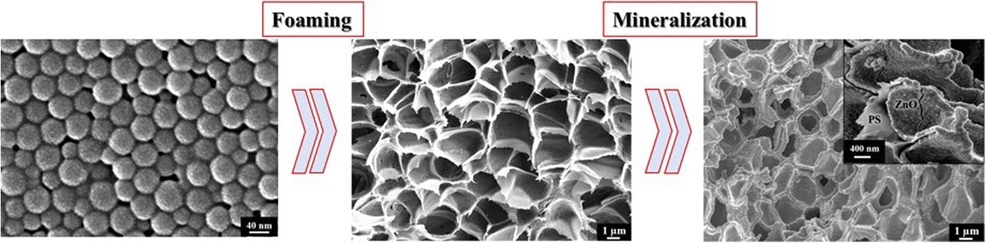

Goal of the project is the synthesis of polymeric (PS & PMMA) nanofoams with adjustable pore size (< 50 nm), geometry and morphology as tailor made substrates for molecular catalysis. To achieve this goal, the influence of the size of the polymeric nanoparticles and the process parameters of the used NanoFoam Continuity Inversion of Dispersions principle will be studied. The nanofoams are functionalized via the hydroxylation of the pore surface. Epoxide groups will be introduced serving as anchoring sites for linker group-bearing catalysts catalyzing the 1,4-addition of boronic acids to enones. The deposition of metal oxide layers increases the stability of the polymeric nanofoams with respect to solvents and high temperature.

Research Questions

- Can we introduce polymer foams with a pore size smaller than 50 nm and a low polydispersity through controlled foaming of a colloidal crystal of tunable polymer nanoparticles?

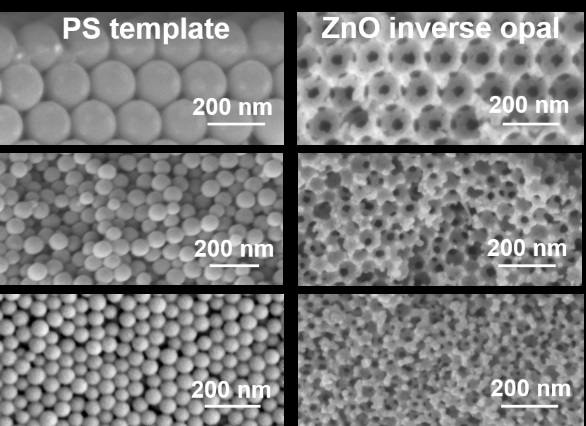

- Can the pore size of polymer foams be tailored by mineralizing a stabilizing metal oxide layer on the pore walls?

- How does the formation of the metal oxide layer depends on the confinement?

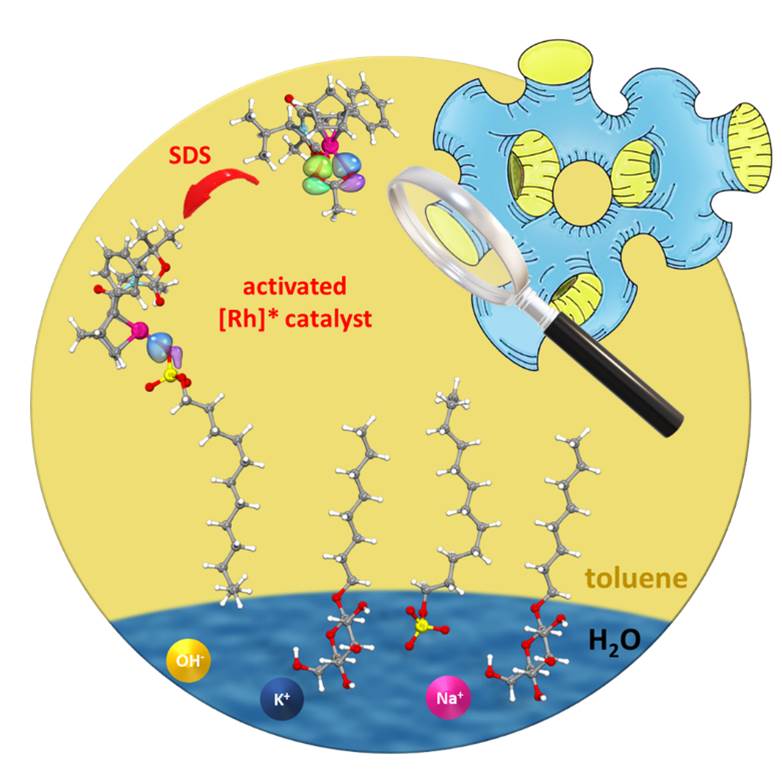

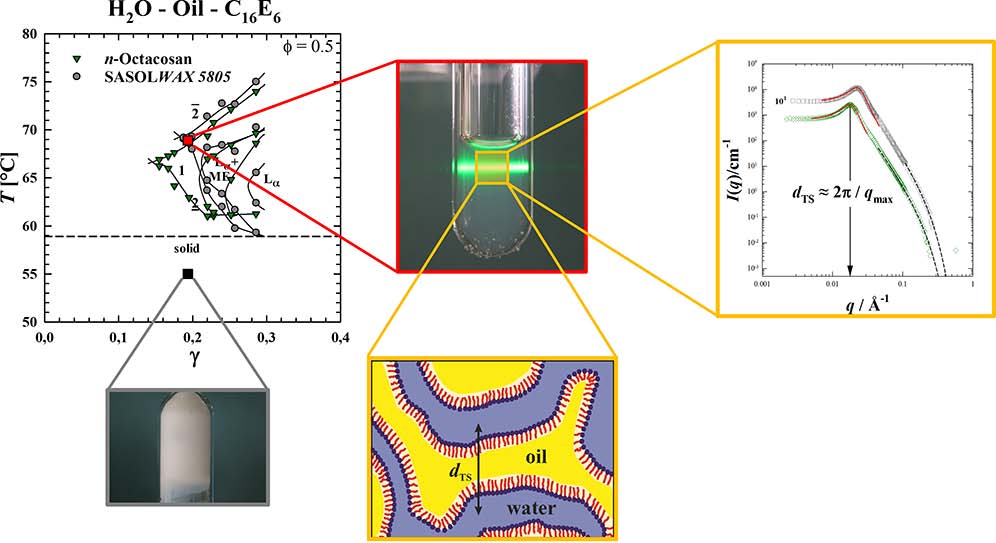

- How does the liquid confinement of tunable microemulsions affect the turnover, selectivity, and kinetics of symmetric nucleophilic addition reactions?

Hierarchical Silica Inverse Opals as a Catalyst Support for Asymmetric Molecular Heterogeneous Catalysis with Chiral Rh‐diene Complexes

From Macro to Mesoporous ZnO Inverse Opals: Synthesis, Characterization and Tracer Diffusion Properties

Adjustable polystyrene nanoparticle templates for the production of mesoporous foams and ZnO inverse opals

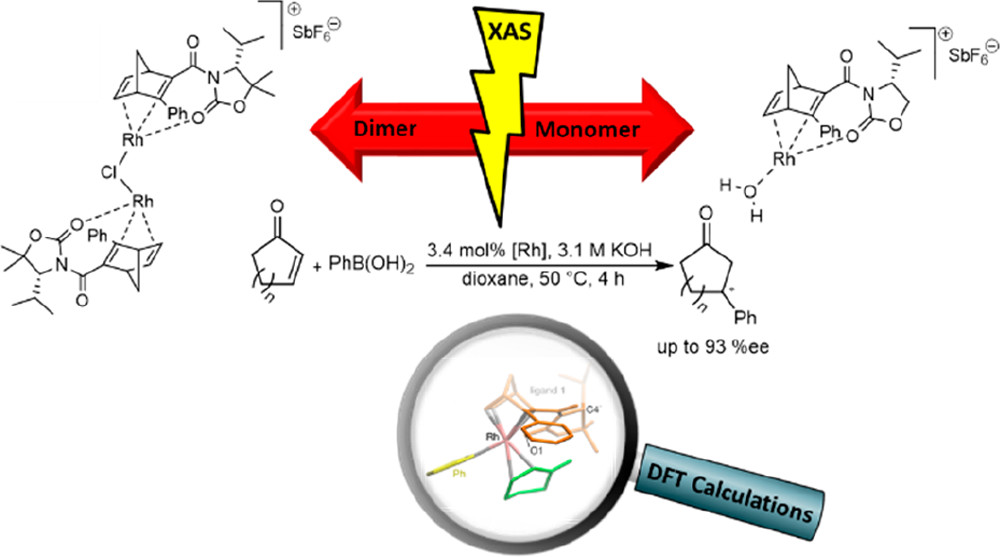

Experimental and Theoretical Study on the Role of Monomeric vs Dimeric Rhodium Oxazolidinone Norbornadiene Complexes in Catalytic Asymmetric 1,2- and 1,4-Additions

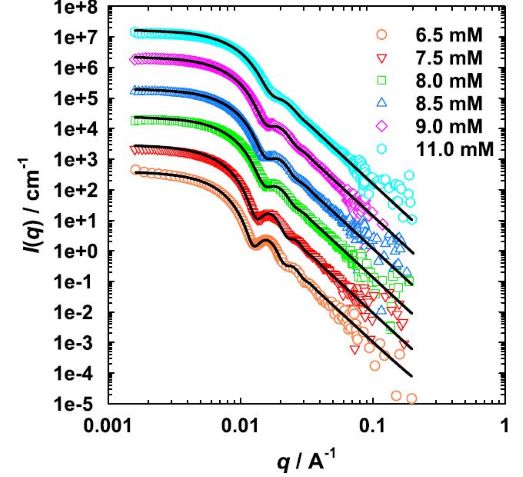

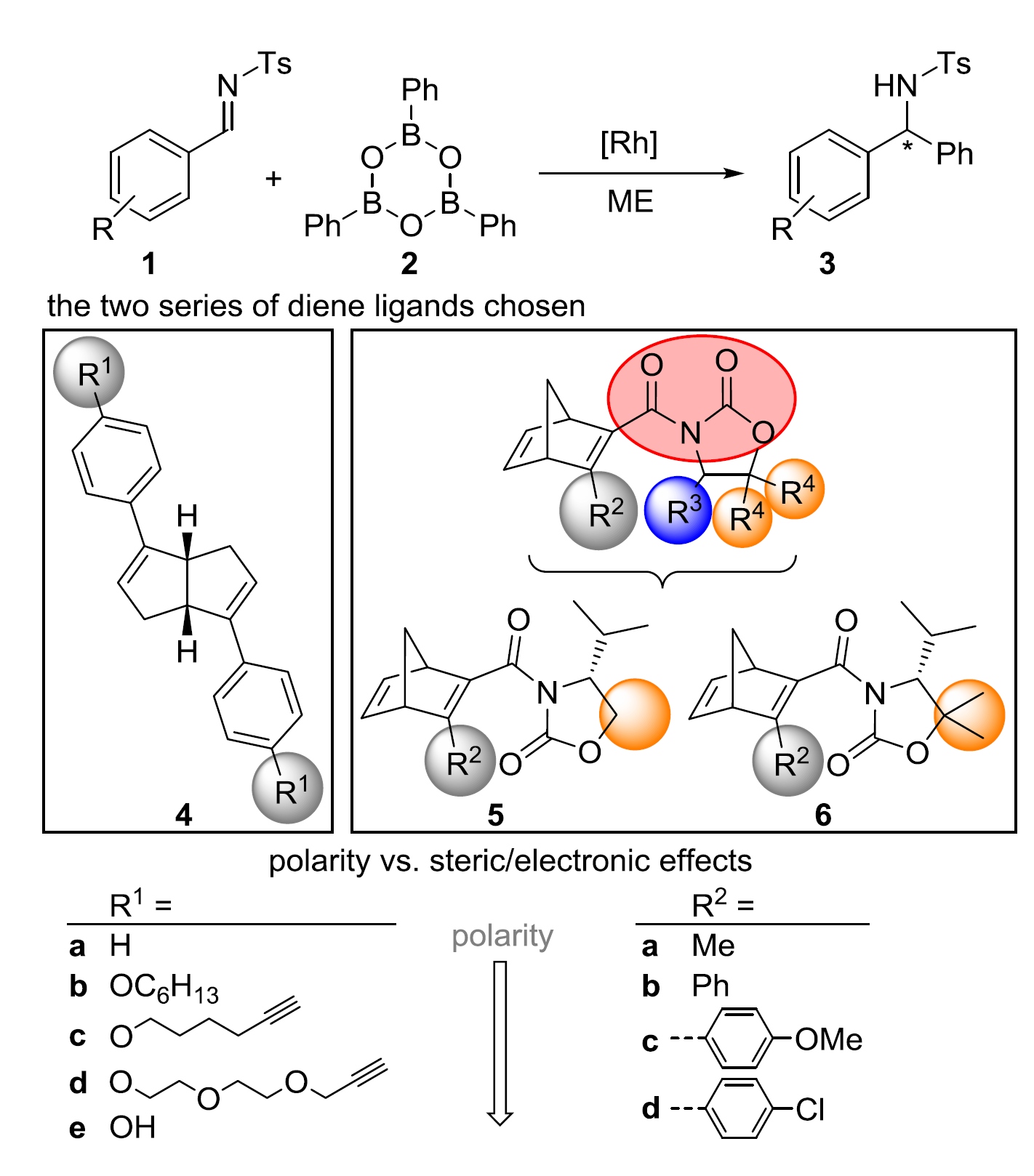

Asymmetric Catalysis in Liquid Confinement: Probing the Performance of Novel Chiral Rhodium Diene Complexes in Microemulsions and Conventional Solvents

M. Deimling, M. Kirchhof, B. Schwager, Y. Qawasmi, A. Savin, T. Mühlhäuser, W. Frey, B. Claasen, A. Baro, T. Sottmann and S. Laschat

Chem. Eur. J. 2019, 25, 9464-9476.

Please find the submitted version of the article on the homepage of the Laschat-group.